100% natural stone surface

Real stone adventages

- Fast implementation (1220x610 mm, 2100x1050 mm, 2400x1200 mm or even bigger sheet sizes)

- Extra durability (30 years warrantee)

- Weather- and frost-resistant

- Tested construction product

- Slightly bendable and flexible

- Manufactured using the ISO 9001:2015 manufacturing process

- 100% natural stone (sandstone, limestone, clay slate, mica slate)

- 35 different structures

- Extra thin (1.2-3.0 mm)

- Extra light (1.5-3.0 kg/nm)

- Easy to work with

- Easily stickable

Made of real rocks

The SlimStone stone veneer sheets were made by separating different layers of natural slate, limestone and sandstone rocks. The natural layer of stone, about 0.4 to 2.0 mm thick, which is separated during the isolation mechanical process, forms the upper part of the product, while the back side is a polyester sheet reinforced with fibreglass to ensure appropriate strength and form stability.

Good to know

Essential characteristics

- Mass per unit area: 1,45 – 3,25 kg/m2* (MSZ EN ISO 10545-3: 1999)

- Adhesive strength >0,5 N/mm2 (MSZ EN 12004-2:2017)

- Water absorption 0,51 – 4,0 m% MSZ EN ISO 10545-3:2018

- clay slate: 2,50%

- mica slate: 1,90%

- sandstone: 2,10%

- limestone: 0,90%

- Frost resistance 100 cycles (suitable) MSZ EN ISO 10545-12:1999

- Resistance to thermal shock 10 cycles (suitable)** MSZ EN ISO 10545-9:2013

- Water vapour permeability (µ) NPD***

- Reaction to fire: D – s3, d0 **** MSZ EN 13501- 1:2007+A1:2010

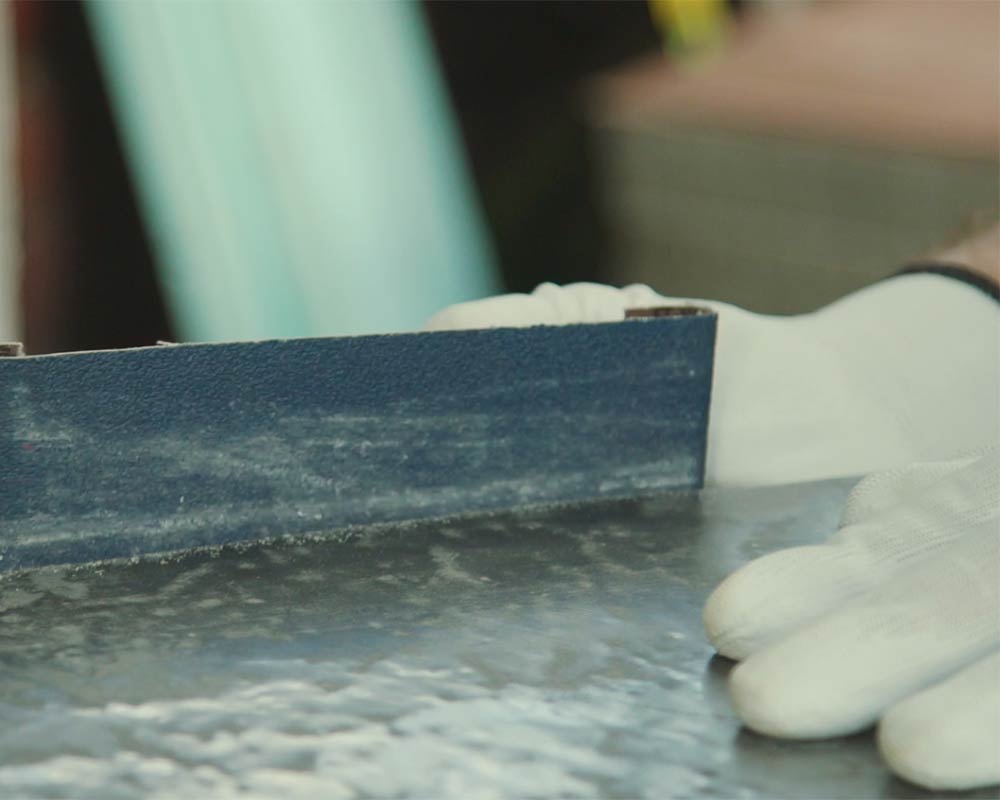

Cutting and machining

The SlimStone stone veneers can be machined with any standard DIY tool, so they can be cut, drilled, milled, cut into pieces, bent, pressed, etc. The products can also be machined with woodworking machines. The use of diamond tools is recommended for industrial processing.

Base surfaces

The SlimStone stone veneer can be applied to MDF or HDF panels, foam sheets, melamine, concrete, brick, plastered walls, drywall, plywood and natural wood surfaces as well as metal, acrylic and other plastic sheets.

Resistance to light, heat and temperature

The natural stone surface layer of the stone veneer is UV-resistant and resistant to the hot sun for decades. Glued to the base surface, the SlimeStone stone veneer is able to withstand the high thermal shrinkage or expansion of most standard building materials. The SlimeStone stone veneer can withstand high temperatures (up to 80 °C) and freezing (up to -40 °C) without cracking.

Bendability

The SlimeStone veneer sheet can be bent with the same flexibility as any plastic sheet product. The back cover used provides sufficient strength and flexibility. The SlimeStone stone veneer sheets can be bent along their length of 1,220 mm to a radius of curvature of about 400 mm.

Installation

Clean, e.g. with a brush, and degrease the base surface before applying the adhesive; remove any oil stains, dust or other impurities. In some places, depending on the adhesive used, it may be necessary to prepare the back side of the SlimStone stone veneer sheet with a solvent or another primer recommended by the adhesive manufacturer. It is advisable to test the adhesive on a surface area before final application. The stone veneer covering may be prone to deformation during the bonding time of the adhesive; take this into account when gluing.

Gluing outdoors or on heat-insulated facades

Due to its light weight, the SlimStone stone veneer sheet is ideal for covering the exterior façade of buildings without brackets, by gluing. For outdoor coverings, we recommend polyurethane or MS-Polymer adhesives with increased bearing capacity. SlimStone Marble Silicone products have worked well as grouting material. Before outdoor use, please refer to our SlimStone façade guide, which presents a possible technical solution and does not qualify as expert advice. The existing surface may need to be reinforced, and the surface to be glued must have a bearing capacity and must be dry and free of peeling parts. In connection with the technical solution suitable for you, please be sure to consult your design architect and the installing contractor before using it.

IMPORTANT: From a fire protection point of view, the SlimStone sheets have D – s3, d0 performance. For this reason, their installation is limited in respect to tall buildings (taller than ground floor + one floor), public institutions, escape routes, etc., and is only possible as defined by law or by using fire-retardant areas. Please check the conditions of exact applicability by involving a design architect.

Grouting

With the SlimStone stone veneer sheets, you can create a traditional tile effect by leaving a grouting gap between smaller sheets cut to size and shape.

Experience has shown that water-based epoxy resin grouting can be suitable indoors for filling the gap between the sheets. A silicone-based grouting material with high flexibility (SlimStone – SILICONE 32 colours) has also worked well outdoors.

If the base surface is deepened just below the joint gap, a deeper grout joint can be formed as desired. The use of cement-based or acetic acid grouting material is not recommended. Check with the grouting material distributor before use.

Surface treatment

Similarly to most natural stone coverings, the SlimStone stone veneer sheets can be provided with a protective, water- and oil-repellent, and surface polishing coating. Since the covering materials are offered in different gloss or lustre levels, we recommend that you ascertain their reflectivity before application to ensure that they have the desired effect.

The covering impregnation agent is a sealant penetrating the stone material, which provides protection against water and oil stains, and protects the stone surface. The sealing effect usually lasts for years or decades. The use of SlimStone impregnation agents is recommended for both indoor and outdoor use.

When pre-impregnating stone veneer covers, be very careful not to get the impregnation agent on the back of the covering because it prevents the adhesive from adhering.

Most natural stone surfaces can be protected by a single treatment with the product called SlimStone Stain Repellent Nano-Effect. It provides protection against oily, greasy dirt and forms a water repellent layer on the surface of the covering. We recommend it for protecting walls, ceilings and other less used surfaces, kitchen surfaces, hotels, public institutions, fireplace coverings, etc. The SlimStone Nano-Effect product also meets food safety requirements. For limestone and sandstone coverings, the more efficient SlimStone Pearl Impregnator surface treatment agent is highly recommended for outdoor use. Please note the information about use on the products!

IMPORTANT: Perform a colour test before using any surface treatment agent.

Surface sealants

We recommend the SlimStone Stone Sealer satin finish (glossy) or SlimStone Stone Sealer matte finish (matte) product for heavily used surfaces (e.g. furniture front, washbasin counter). These sealants form a glossy or matte acrylic covering on the surface of the stone veneer, clog the pores and make the surface resistant to water and dirt in the long term.

Please refer to the manufacturer’s information on use.

Cleaning and caring

No adhesives or grouting material may be left on the surfaces of SlimStone stone veneer products after their pre-impregnation, during their laying and grouting. If this does happen, use a floor cleaner or cement veil removal product (in a highly diluted state with a short duration of action and a preliminary test).

We recommend using the product called SlimStone Oil and Grease Remover Paste to remove oil and grease stains as soon as possible after staining.

The above surface treatment operations can only be carried out after the surface has dried out completely. Surface scratches can be easily removed by rubbing the surface with a soft cloth.

It is recommended to clean all types of natural stone surfaces, including those impregnated, indoors regularly with a suitably moistened soft tool. Use a water-diluted natural stone cleaning and care agent. For example, we recommend SlimStone Crystal Clean or SlimStone Mild Stone Soap, which can be used to clean and care for the stone surface at the same time, which is thus not damaged and becomes more beautiful, gaining a more saturated tone during regular use.

Storage

Before use, SlimStone products should be stored in a dry, preferably frost-free place protected from direct sunlight, in a horizontal position, protected from the harmful effects of the weather. Any temperature variation that may cause deformation should be avoided. During storage, pay attention to the protection of the stone veneer surface. It is recommended to place an intermediate protective layer between the slate surfaces of the stone veneer sheets in the event of stacking.

Transport

The SlimStone stone veneer products can be easily and economically transported due to their extremely light weight. The stone veneer sheets are delivered packaged in stable, customised cardboard boxes designed for Stixstone products.

Nominal dimensional tolerance

The nominal dimensional tolerance is ± 1 to 2 mm in length and width and in right angles.

Quality assurance

Quality assurance is implemented using an EU quality management system. The SlimStone stone veneer coverings are tested construction products and meet the essential requirements of European health, safety and environmental legislation. Production is controlled in accordance with the ISO 9001:2015 standard. Our company undertakes a 5-year express warranty + a 5-year implied warranty for the products we sell.

Certificate of conformity

The SlimStone stone veneer coverings have passed the laboratory tests and are provided with the certificates required by law in Hungary, on the basis of which they can be designed and installed as building materials indoors and outdoors. Identification number of the National Technical Assessment issued by ÉMI Építésügyi Minőségellenőrző Innovációs Nonprofit Kft.: A-134/2015.

The conformity of the SDA MS-Adhesive Sealant adhesive distributed by our company with SlimStone ultra-thin stone veneer sheets is certified by an expert’s report issued by the Building Materials and Building Construction Laboratory of the Department of Building Materials and Building Construction of the Technical University of Budapest. Project number: OM: FI23344

So easy quick to work with

1.

Mark the desired size on the cover with a scratch pen.

2.

Cut the cover to the desired size with a thin, continuous-edged cutting disc or circular saw.

3.

You can cut from the back or from the side of the stone. If you cut from the back side, take care of the stone side so that it is not damaged.

4.

If the cut side needs to be adjusted to tolerance, you can also do this with sandpaper.

5.

Gluing the veneers is very easy. For convenient work, it is recommended to use an electric pressure gun.

6.

The SlimStone special stone veneer glue must be applied to the back of the boards in PARALLEL strips at a distance of 5-7 cm from each other. With a beak thickness of approx. 4 mm.

7.

Carefully squeeze out the air from under the panels with a rubber roller.

8.

Make sure to leave a joint gap of 4-5 mm between the covering sheets. Press the SlimStone matt silicone sealant into the joint with a 45° beak. Remove it with the usual technology, then you can easily wipe off the spilled silicone residues from the impregnated stone surface after the grout solidifies.

9.

edge formation To create positive edges, grind the matching edges to 45°.

10.

At the corner, let one of the sheets overhang by 2-3 mm, and a fill the inner half with small SlimStone silicone with grout. This silicone material will hold the to flexibly hold the inner edge of panels together.

11.

Glue the other one - also ground to 45° edge - matching panel and pull it together at edges. Silicone leaked along the joint in the evening material can be wiped off the impregnated stone surface.

12.

Make sure that you always use the same paving slab to turn around the corners, so that the pattern of the stone will match and a perfect 'block of stone' look will be achieved.

Are you ready to get to know more about our stone veneers?

Contact us or download our product brochure…